Mirror Silver Coating, Stainless steel, Aluminium, Titanium press working.

Disc Spring

Applicable fields of Disc Springs

- Machining Centers

- Automobile Components

- Earthquake Resistant Structure Components

- Precision Instruments

- Construction Machines

- Optical Instruments

Features of IWATA's Disc Springs

<Extensive Lineup>

- 1. Carry two different Standards, JIS (Japanese Industrial Standards) and IWT Industrial Standards

- 2. Provide 140 kinds of product types

- 3. Meet orders of users' prototypes and mass production

<High Quality, High Abrasion Resistance and High Shock Absorbability>

- Develop Disc Springs with high abrasion resistance and high shock absorbability, mainly by the use of SK-85M or SUP-10

※ SK-85M

1. Carbon tool steel, high carbon content material

2. High carbon content material makes Disc Springs high Abrasion Resistance

※ SUP-10

1. Spring Steel, high plasticity material

2. High plasticity material makes Disc Springs high Shock Absorbability

<High Load stability>

- IWATA's high precision manufacturing technology enables Disc Springs excellent load stability and sliding characteristic

IWATA's Disc Springs Achievement

- Compact design of users' products, by comparison of the use of coil springs

- Long and stable operation of Machining centers

- Smooth movement of precision instruments

- Light weight and miniaturization of optical instruments

Usage Examples of IWATA's Disc Springs

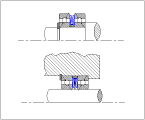

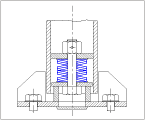

inner and outer rings of bearing

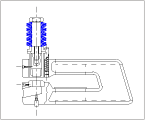

wire clamp device

electro magnetic clutches

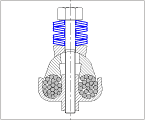

die cushion

damper device for building base isolation

small disk brakes

hole space punch unit

isolation device for large-scale construct

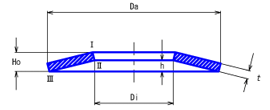

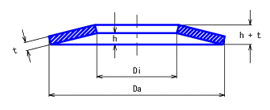

Specification

| Standard |  |

|

|---|---|---|

| For bearing |  |

- Disc Spring,

Retaining Ring - Disc Spring

- Retaining Ring

- Surface Coating,

Mirror Silver Coating - Surface Coating

- Mirror Silver Coating